Ultrasonic cold welding machine

The best tool for casting defect hole welding

20000/second vibration output | 7-inch touch screen

Can be welded in any location | Full digital control

“The prerequisite of a fast welding”

Ultrasonic vibration cold welding system

High efficient, fast welding speed

Use the new generation of ultrasonic vibration system, higher performance lower heat and longer working time.

more than 20000/second vibration output, high frequency discharge of electrode material and transfer to the workpiece.

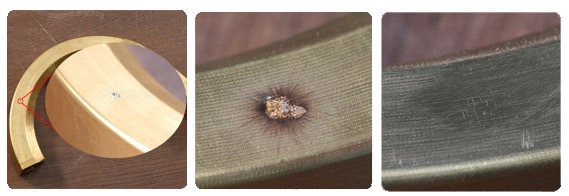

Angle broken

Porosity defect

Shrinkage defect

Sand hole defect

Blow hole defect

Crack defect

Suitable for all kinds of castings and defects

After welding very high deposition density and low porosity rate,

most of the defect holes can be perfectly welded at one time.

AWE-19US supporting many different types of welding electrode, choose the suitable electrode can adjust the hardness of the welding surface easily to match different requirements.

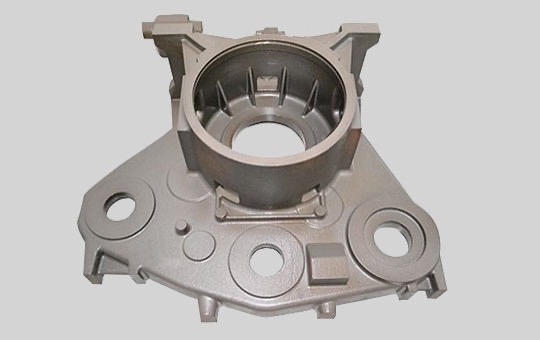

Ductile iron

Auto parts / Windmill casting

Gray iron

Cylinder / Textile machinery

Steel

Mould / Casting

Aluminum

Engine parts / Automobile hub

Copper

Power electrical facilities

Silver

Industrial / Crafts

Cast iron

Pump / Industrial castings

Brass

Ship parts / Precision instruments

Other alloys

Auto parts / Industrial parts

No more difficult to repair

any position

The welding electrode can be bent to any angle to weld any narrow or deep positions. Now more castings can be saved !

No argon gas required during welding, low welding cost. Strong combination.

Metallurgical combination

Cold welding process will form a metallurgical combination. Use the right type of electrode cold welded position will strongly combined into the casting. Will not drop during machining or grinding.

“Big screen and digital control to make it easier to use”

7-inch touch screen

No physical buttons, more durable

7-inch touch screen clear enough to operate, four welding mode selection, quickly change the parameters for welding different materials.

Full digital control

32 bit ARM cpu, smart control.

High quality electric components to guarantee the machine stability and longer using life.

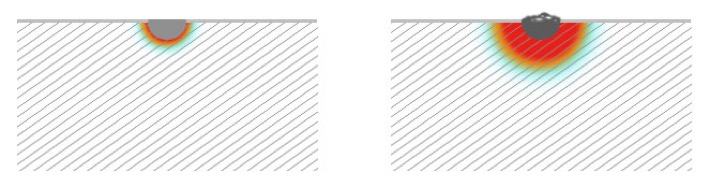

ATOM cold welding

Very small heat affected zone

Traditional welding

Big heat affected zone

Very small heat affected zone

No change of micro structure

Use cold welding technology, you can touch the welded surface immediately after welding.

The surface is just worm not hot. Very small heat transferred into the casting compare to traditional welding machine.

It will not anneal the casting and keep the mechanical structure unchanged.

CASTING REPAIR

MOULD REPAIR

TUNGSTEN COATING

USED EQUIPMENT REPAIR

AWE-19US PARAMETERS

MODEL:

AWE-19US

INPUT VOLTAGE:

AC220V

POWER OUTPUT:

1500W

VOLTAGE OUTPUT:

1 ~ 9

FREQUENCY OUTPUT:

WEIGHT:

1 ~ 9

15KGS

CURRENT OUTPUT:

MACHINE SIZE:

1 ~ 9

405*220*290MM

WELDING ROD DIA.:

1.0 ~ 3.0MM

PACKAGE:

BOX

Copyright © 2022 Atom welding equipments. All rights reserved.