What types of defect hole can be welded by ATOM cold welding machine ?

Technology & articles

Welding demo is available at your location where we have distributors !

Most of the foundries will have rejection rate from 10%-30%, blow hole defect, sand hole defect, shrinkage defect, porosity hole defect etc. Some of them on raw surface, some on machined surface.

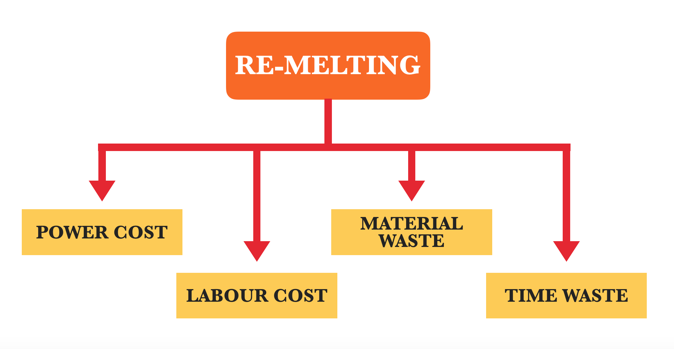

The end customers will not accept such castings with even one defect hole, so the only solution is to remelt.

In order to reduce the rejection rate, they have to check all the process including :

Even that still difficult to find the real reason and can’t find the solutions. To remelt will waste a lot of money, especially for bigger size castings.

Actually for all those defect castings, around 70%-90% only have few small defect holes. And those castings can be welded by our cold welding machine.

So for a 500MT foundry, every month can save unto USD40000.

ATOM cold welding machine will be your best tool to save cost.

Copyright © 2022 Atom welding equipments. All rights reserved.